SHURflo Pressure Switch for Pump: Complete Guide & Tips

Have you learned the Shurflo Pump pressure switch usually ceases operation at 55 psi yet can self-activate up to 6 feet? Understanding how the Shurflo Water Pump pressure switch operates is critical for everyone looking to improve Water flow in recreational vehicles and diverse setups. This in-depth handbook provides RV enthusiasts, contractors, and home repair buffs with detailed knowledge. It covers the pressure switch’s operation, calibration techniques, mounting methods, and maintenance tips. This Shurflo water pump pressure switch data is imperative whether you’re troubleshooting or improving your pump’s operation.

Main Points

- The pressure switch can shut off at 55 psi for optimum performance.

- The bypass begins to engage at 30 psi and reaches full opening by 65 psi.

- Be cautious of overlapping bypass and shut-off pressures to avoid malfunction.

- Its adjustable settings allow customization to match system requirements.

- Proper inlet performance demands at least 1/2” I.D. tubing.

- Thermal protection prevents overheating while the pump runs dry without damage.

- To ensure efficient operation, observe the maximum intermittent run time of 20 minutes each hour.

Comprehending the Shurflo Pump Pressure Switch

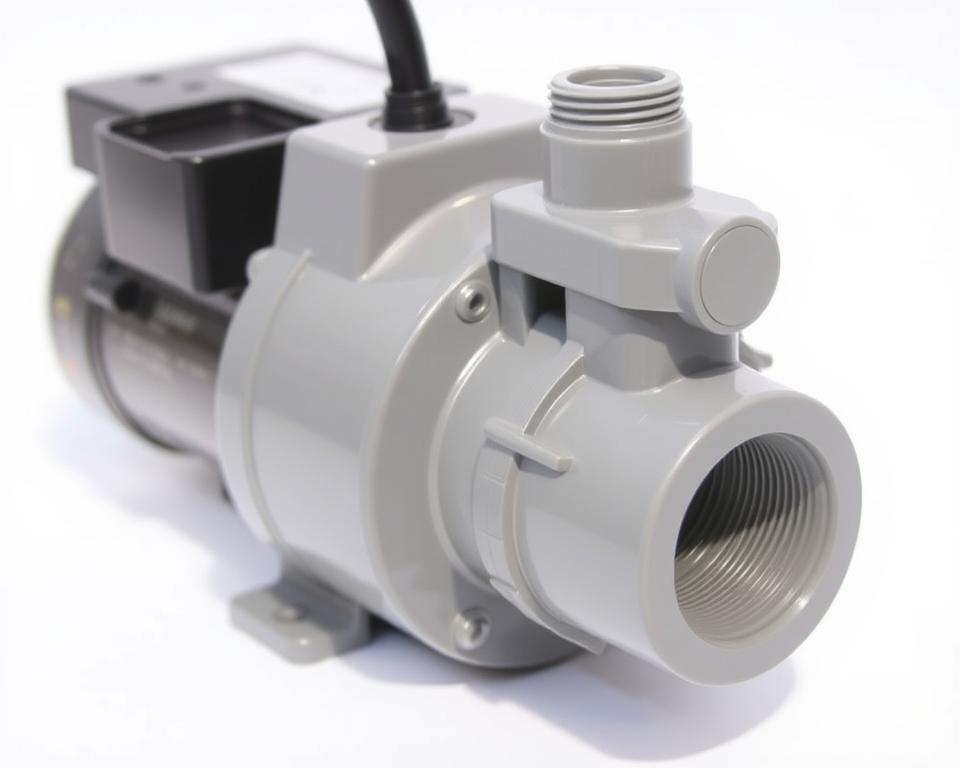

The Shurflo pump pressure switch is key in controlling Water flow for pumps. It’s crafted for Water transfer, vital for recreational vehicles and marine setups. We’ll explore its function, how it works, and its merits in this section.

Overview of the Shurflo Pump Pressure Switch

A Shurflo pump pressure switch regulates Water system pressure by automatically managing the Pump. It engages or disengages the pump based on pressure levels, providing continuous Water flow and shielding the Pump from harm caused by overuse.

How the Pressure Switch Works

Its primary function is to track Water pressure. It triggers the pump when pressure diminishes, ensuring a constant supply. At proper pressure, the pump is switched off. This not only guarantees a steady flow but also saves the pump from overworking. You can adjust the settings to suit specific requirements.

Advantages of the Shurflo Pressure Switch

Choosing a Shurflo pressure switch brings several benefits:

- Automated Control: It ensures smooth pressure regulation through automated adjustments.

- Reduced Energy Consumption: The switch lowers energy use by operating the pump only when needed.

- Minimized Strain: It decreases strain on the pump, reducing repair costs over time.

- Optimal Pressure Maintenance: Proper pressure control is crucial for uninterrupted water delivery in RV applications.

Its adjustable options make the Shurflo pump pressure switch versatile, fitting various needs, including the shurflo 2095 replacement or other parts.

Installation Tips for Your Shurflo Pump

Correct installation of your Shurflo pump and its pressure switch is key to optimal performance. Attention to proper placement and plumbing details is necessary. Doing so helps avoid common problems that could arise during use.

Optimal Mounting Techniques

To ensure optimal performance, mount the pump on a solid surface no more than 6 feet from the storage tank. This makes it easy to access and keeps it functioning well. If mounting it vertically, make sure the pump head faces downward to stop liquid from entering the motor chamber.

The use of flexible high-pressure hose at inlet and outlet ports decreases vibration and noise and promotes effective water transfer. Avoiding sharp bends in the tubing is important; they can lead to kinks that hinder water flow.

Key Plumbing Guidelines

Proper plumbing is fundamental to the effective operation of the Shurflo pump pressure switch. Utilizing a minimum of 1/2″ I.D. plumbing is essential to stop cavitation. Cavitation can lead to excessive back pressure and diminished flow, so its prevention is key. Using a 50-mesh inlet strainer prevents debris from entering the pump.

Also, keeping the number of elbows and valves in the plumbing to a minimum is advised to lessen flow restrictions. A streamlined plumbing configuration is crucial for maximizing pump efficiency.

Calibrating Your Shurflo Pump Pressure Switch

Proper calibration of your Shurflo pressure switch is essential for optimal operation. Correct adjustments guarantee smooth system operation and lower pump strain. Locate the Allen screw on the top of the pressure switch to begin adjustments. This screw is key for adjusting the shut-off pressure settings.

Adjusting the Cut-off Point

To adjust the shut-off pressure, twist the set screw clockwise—this raises sensitivity, leading to increased pump cycling. It boosts the shut-off pressure, ensuring the system maintains strong pressure. A counter-clockwise turn diminishes sensitivity and limits pump cycling.

It’s wise to test your adjustments by running the shower—the pump must run during water flow and shut off when the flow ceases. Set the shut-off pressure to be no less than 10 PSI under the bypass opening level to minimize potential malfunctions.

Bypass Configuration Explained

Proper bypass configuration is critical to safeguard the switch and enable smooth operation. When set appropriately, it permits water to cycle from the discharge back to the inlet at a defined pressure. Proper bypass calibration preserves overall system efficiency. If set too high, the pump risks not shutting off, resulting in potential damage.

If you find these settings difficult to configure, obtaining professional guidance is recommended. Their expertise can prevent missteps and preserve your system’s integrity.

Resolving Typical Issues

Troubleshooting typical Shurflo pump issues necessitates recognizing various problems. Problems may arise from both electrical faults and physical component damage. Recognizing these issues is key to troubleshooting and boosting pump efficiency.

Pump Fails to Start or Overcycles

If the pump fails to start, first inspect electrical connections. Ensure that fuses and switches are in working condition. Rapid cycling might mean air leaks in plumbing or a defective strainer. Examine inlet and outlet valves to ensure they are not obstructed. Addressing these pump pressure switch issues is crucial to maintain performance.

Pressure Switch Not Functioning Properly

A defective pressure switch might inhibit pump activation or cause perpetual cycling. Ensure that the switch settings are correct and free of obstructions. If problems remain unresolved, a switch replacement may be required. Monitoring these shurflo switch issues is key to maintaining pump performance.

Identifying Vibration and Noise Problems

Excessive noise during operation may indicate loose connections or faulty installation. Check that all connections are firm and the pump is properly installed to decrease noise. The use of flexible hoses assists in absorbing vibrations, reducing shurflo pump noise issues for a smoother performance.

Caring for Your Shurflo Pump Pressure Switch

Regular upkeep is crucial for your Shurflo pump’s efficient operation and durability. Upkeep involves cleaning, inspections, and proper winter preparation. Good maintenance practices boost performance and prevent issues.

Strainer Maintenance

Strainer maintenance is essential for keeping your Shurflo pump in top condition. Debris buildup can obstruct water flow, causing problems. Ensure periodic cleaning of the strainer to prevent flow obstruction. A well-maintained strainer reduces the pump’s workload, aiding in its upkeep.

Routine Check Guidelines

Routine examination of pump components is essential for early problem detection. Establish a routine to check:

- Wiring and connections for deterioration

- Fluid levels in the tank

- Tubing condition and secure fittings

- The pressure switch’s functionality

Tightening connections and ensuring proper switch function boosts efficiency. Regular maintenance significantly prolongs pump longevity.

Pump Winterization Guidelines

Preparing your pump for winter is essential to avoid frost damage. For successful winter preparation:

- Completely empty the Water tank

- Eliminate any residual Water from the plumbing

- Use non-toxic antifreeze to safeguard seals and components

These steps shield your system from cold damage and prevent costly fixes. This also readies the system for the next season.

Essential Replacement Components for Shurflo Pumps

Optimal performance of your Shurflo pump depends on superior replacement parts. Key components from the Shurflo 2095 series are indispensable for system reliability. Focus on essential elements such as pressure switches, diaphragms, and valves. Authentic Shurflo pump components ensure system dependability and longevity.

Overview of Shurflo 2095 Spare Parts

A variety of Shurflo 2095 replacement components are available to address different needs. They work harmoniously to enhance performance and prevent problems. Every component plays an essential role in sustaining pump performance.

- Pressure switches: Regulate the activation cycles of the Pump

- Diaphragms: Maintain proper Water flow and prevent leaks

- Valves: Regulate pressure and ensure smooth operation

Where to Purchase Shurflo Replacement Parts

For those in search of Shurflo parts, Installation Parts Supply is a reliable supplier. They offer a full range of Shurflo pump components to meet every repair and upkeep requirement. Genuine parts from this supplier ensure lasting pump performance.

In Closing

This pressure switch is central to ensuring consistent Water flow and longevity in various uses.

By grasping how it works, how to maintain it, and how to fix common problems, you can significantly enhance your Water system’s lifespan. Regular maintenance minimizes problems, increasing the Pump’s reliability, as evidenced by a strong 4-year performance history.

Easy, budget-friendly upkeep is possible through interchangeable components for both 12V and 24V versions. Ensure accuracy by confirming part numbers: 94-890-08 for 12V and 94-890-09 for 24V to avoid needless costs and prolong your pump’s life.

Clearly, with proper care, Shurflo pumps are highly reliable. Expect enhanced performance from the latest models, reflecting the brand’s dedication to quality. Installation Parts Supply remains a reliable partner for expert setup and genuine replacement parts. By following these maintenance tips, you secure years of reliable, efficient performance.